Multi-Location Asset Transfers: Processes That Scale

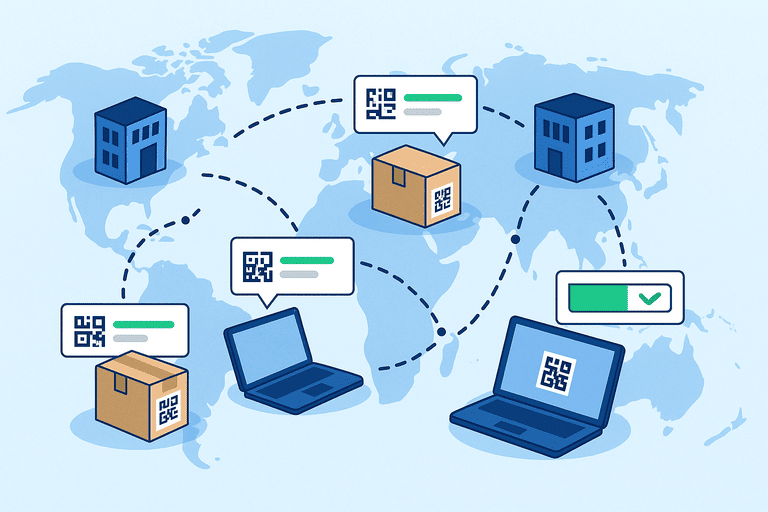

Learn how to manage multi-location asset transfers efficiently with standardized workflows, real-time visibility, and scalable tracking practices.

Introduction

As organizations expand across cities or countries, their asset management challenges multiply.

Transferring equipment between offices, warehouses, or branches requires not just logistics — it requires coordination, documentation, and control.

Without structured transfer processes, companies risk:

- losing track of assets in transit,

- mismatched records between sending and receiving sites,

- or delays caused by manual confirmations.

This guide explores how to build scalable, repeatable processes for multi-location asset transfers — ensuring visibility, accountability, and accuracy every step of the way.

1. The Complexity of Multi-Location Transfers

Unlike internal movements within a single facility, inter-site transfers involve:

- Multiple custodians (sender, courier, receiver)

- Different inventory systems or databases

- Transit delays or customs for cross-border shipping

- Varying tagging standards and approval workflows

A lack of unified procedures can quickly lead to lost or duplicated assets, impacting audits and insurance claims.

Common failure points:

- No record of transfer authorization

- Missing proof of dispatch or delivery

- Asset IDs changed during transit

- Delayed system updates

Standardization is the key to scaling safely.

2. Key Principles of Scalable Asset Transfer Management

1. Centralized Record Keeping

All transfers should originate from a single system of record — ensuring both source and destination sites reference the same asset IDs and transfer status.

If multiple teams touch the same assets, strong cross-team transparency reduces “it’s not ours” handoff failures: Inventory Transparency and Cross-Team Collaboration.

2. Transparent Handoffs

Each stage of the process (dispatch, transit, receipt) must have a timestamp and responsible user logged.

3. Real-Time Visibility

Stakeholders should see transfer progress, location, and expected arrival through dashboards or notifications.

4. Standardized Documentation

Every transfer should include:

- Asset list with tag IDs

- Sender and receiver signatures

- Condition reports (before and after)

- Proof of shipping and delivery

5. Automation Where Possible

Use barcode or QR scans to auto-update transfer statuses rather than relying on manual spreadsheet edits.

For field-friendly scans and proof capture (photos, notes, timestamps), QR-powered mobile inspections are a strong fit: The Power of Mobile Inspections — How QR Codes Speed Up Field Work.

3. The Multi-Location Transfer Workflow

Here’s a typical scalable process:

Step 1: Initiation

- Department or manager requests a transfer.

- Approval workflow checks asset availability and eligibility.

- System generates a unique Transfer ID.

Step 2: Preparation

- Assets are verified and scanned out of the current location.

- Condition photos and notes are logged.

- Packaging and shipping details recorded.

Step 3: Transit Tracking

- Status changes to “In Transit.”

- Shipping carrier and tracking ID linked.

- Optional integration with courier APIs for real-time updates.

Step 4: Receipt and Validation

- Receiving site scans QR codes to confirm arrival.

- Compares received items vs. manifest.

- Updates condition and storage location.

To prevent “silent delays” when the receiving site forgets to validate, automate escalations for overdue receipts: Inventory Notifications and Escalation Workflows.

Step 5: Reconciliation

- System automatically closes the transfer once all assets are validated.

- Exceptions (missing or damaged items) trigger review workflows.

This process minimizes human error and ensures both ends of the transfer are synchronized.

4. Common Challenges — and How to Solve Them

| Challenge | Root Cause | Scalable Solution |

|---|---|---|

| Inconsistent transfer records | Multiple spreadsheets | Use centralized asset tracking database |

| Missing confirmation from receiving site | Manual follow-ups | Automate notifications upon receipt |

| Asset ID conflicts | Different tag formats | Enforce global tagging standard |

| Delayed updates | Offline or paper workflows | Enable mobile scanning for all sites |

| Compliance risks | Lack of audit trails | Store digital proof of every transfer |

Automation tools can also detect discrepancies — for example, when an item marked “in transit” remains so for more than a set number of days.

5. Standardizing Across Regions

For international or multi-region companies:

- Use universal asset ID formats to prevent duplication.

- Store all timestamps in UTC for consistency.

- Include local contact roles for handoff accountability.

- Define clear customs and import/export responsibilities in your SOP.

A standardized global transfer policy avoids confusion and ensures compliance with both local and corporate regulations.

6. Measuring Efficiency and Accuracy

To assess how scalable your transfer process is, track:

- Average time per transfer

- % of completed transfers without discrepancies

- % of late receipts

- % of transfers missing documentation

These KPIs reveal bottlenecks and help improve cross-location coordination.

7. Future Trends: Automation and Real-Time Tracking

Modern tools increasingly rely on:

- GPS-enabled tags to track transit in real time

- Automated triggers when items reach destination zones

- API integrations with shipping services for live updates

These technologies reduce manual reporting and strengthen cross-site collaboration.

Conclusion

As organizations grow, assets will inevitably move — between offices, clients, or even continents.

Scaling these transfers successfully requires visibility, control, and consistency.

By standardizing workflows, automating status updates, and centralizing records, you can ensure assets remain traceable from dispatch to delivery — no matter how large your network becomes.

Related reading

Try InvyMate

Start tracking assets with QR codes and scheduled audits.