How to Run a Cycle Count Program for Shared Resources

Learn how to implement a cycle count program to manage shared resources effectively—boosting accuracy, reducing downtime, and minimizing audit stress.

Introduction

When assets are shared between teams, departments, or locations, keeping accurate records becomes a constant challenge. Full physical audits are time-consuming, disruptive, and often outdated the moment they’re completed.

A cycle count program offers a practical solution—small, regular checks that maintain inventory accuracy year-round.

This guide explains how to design, schedule, and run a cycle count program tailored for shared resources, whether you’re managing tools in a workshop, IT equipment in a coworking space, or devices across a large office.

1. What Is a Cycle Count?

A cycle count is a scheduled process of verifying a subset of your assets instead of performing a full physical inventory.

For shared environments, it helps maintain visibility without pausing operations or waiting for year-end audits.

Key benefits:

- Continuous data accuracy

- Reduced audit stress and downtime

- Early detection of missing or misplaced assets

- Stronger accountability among users

- Reliable forecasting for replacements or repairs

2. Why Shared Resources Require Special Handling

Unlike fixed departmental assets, shared resources move frequently—between teams, projects, or even locations.

These patterns make traditional annual audits unreliable.

Challenges specific to shared assets:

- Frequent handovers create accountability gaps

- Missing labels or outdated tags

- Tools temporarily “borrowed” without logging

- Departments tracking items differently

If your team still tracks shared gear in spreadsheets, this is where accuracy breaks down: Why Spreadsheets Fail at Asset Tracking (And What to Use).

A well-structured cycle count helps uncover discrepancies while they’re still small enough to fix.

3. Designing Your Cycle Count Program

Creating a cycle count plan starts with segmentation and prioritization.

You don’t need to count everything at once—focus on the most critical or volatile asset groups.

Step 1: Segment Your Inventory

Group assets by:

- Category: IT, tools, furniture, safety gear

- Usage frequency: daily-use vs rarely-used

- Value: high-cost assets count more often

- Risk: easily misplaced or shared items

Step 2: Define Count Frequency

| Asset Type | Suggested Frequency |

|---|---|

| High-value IT equipment | Monthly |

| Shared office tools | Bi-monthly |

| Furniture or fixed installations | Semi-annual |

| Consumables | Weekly or rolling count |

Step 3: Assign Responsibility

Assign clear roles:

- Custodians (responsible for area or category)

- Counters (conduct verification)

- Reviewers (validate results and reconcile differences)

Accountability improves when each item has a “home base” or a person in charge.

4. Running the Cycle Count

1. Prepare Your List

Extract a current list of assets by location or type.

Ensure fields like asset ID, tag number, location, condition, and custodian are up to date.

2. Physically Verify Assets

Counters check physical items and compare them against the digital register or tracking system.

Mark each as:

- ✅ Found

- ❌ Missing

- 🛠 Damaged or requires update

For faster verification in the field (and fewer missed items), follow: QR Code Inventory Tracking: Setup Guide for Teams.

3. Reconcile Discrepancies

Investigate any mismatches:

- Check logs for recent transfers or loans

- Verify if tags were replaced or reissued

- Confirm if the asset was retired but not archived

4. Record Adjustments

Document all changes.

If discrepancies exceed thresholds (e.g., >2% deviation), schedule a deeper audit for that category.

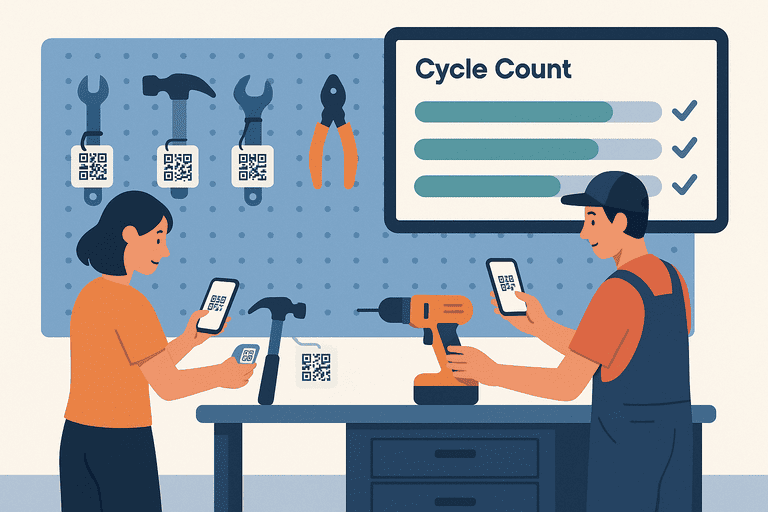

5. Using Technology to Simplify the Process

A modern asset tracking system with QR or barcode scanning reduces manual data entry errors.

Counters can scan items using smartphones and automatically mark them as verified in the system.

Key features that support cycle counting:

- Batch scan verification

- Location-based checklists

- Automatic count scheduling reminders

- Role-based access for counters and reviewers

- Exportable reconciliation reports

To keep the program lightweight (no weekly “big audit”), pair cycle counts with: Bridging Physical and Digital Audits with QR Checks.

These tools allow teams to complete cycle counts without interrupting normal operations.

6. Continuous Improvement: Turning Counts into Insights

Cycle counting isn’t just a verification task—it’s a feedback loop for improving asset policies.

Review each cycle’s data to spot trends:

- Frequent missing items in one department

- Assets often relocated without updates

- Items nearing end-of-life or underutilized

Turn these findings into policy improvements—better check-out procedures, more visible labeling, or adjusted count frequency.

Conclusion

A well-designed cycle count program transforms inventory management from a reactive process into a steady rhythm of accuracy and accountability.

Instead of facing one overwhelming annual audit, you build a culture of consistency—where shared resources are always traceable, visible, and properly maintained.

Related reading

- Inventory Audit Checklist: What to Verify and How Often

- How Inventory Transparency Improves Cross-Team Collaboration

- Risk Management in Asset Tracking — From Theft to Data Breaches

- Role-Based Permissions in Inventory Systems: What’s Safe

- The Hidden Costs of Poor Inventory Management (and How to Avoid Them)

Try InvyMate

Start tracking assets with QR codes and scheduled audits.