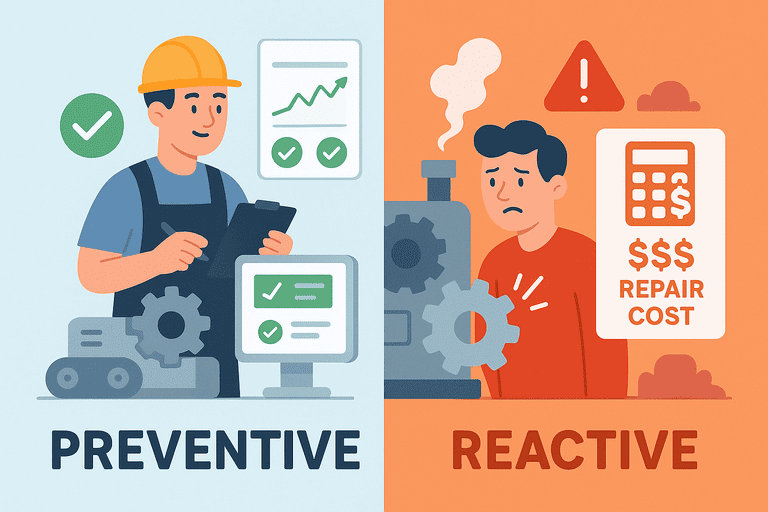

Preventive vs Reactive Maintenance: Cost Comparisons

Learn the key differences between preventive and reactive maintenance, how each affects long-term costs, and when to invest in proactive asset care.

Introduction

Every organization that owns equipment — from IT devices to manufacturing tools — must choose between fixing issues after they occur or preventing them altogether.

This decision defines your maintenance strategy — and directly impacts your bottom line.

Understanding the cost trade-offs between preventive and reactive maintenance helps businesses plan budgets, reduce downtime, and extend asset life cycles.

1. Preventive vs Reactive Maintenance: The Basics

| Strategy | Description | Example |

|---|---|---|

| Reactive Maintenance | Fix assets only when they fail. | Repairing a broken projector or printer. |

| Preventive Maintenance | Regular inspections or servicing to avoid breakdowns. | Cleaning, calibrating, or updating equipment before issues arise. |

At first glance, reactive maintenance seems cheaper, since you pay only when something breaks.

But over time, unplanned failures lead to downtime, higher repair costs, and early asset replacement.

2. The True Cost of Reactive Maintenance

Reactive maintenance often feels convenient — “we’ll fix it when it fails.”

However, this short-term approach hides unseen costs.

If breakdowns happen during checkouts/returns (shared equipment), tightening the checkout process can reduce “mystery failures” and missing context: Designing an Asset Checkout Flow UX That Works.

Hidden costs include:

- Downtime: Equipment failure halts operations.

- Emergency repairs: Urgent service calls are expensive.

- Asset replacement: Neglected wear reduces lifespan.

- Lost productivity: Teams wait for fixes.

- Data loss or safety risks: Especially in IT or manufacturing environments.

Studies suggest reactive maintenance can cost 3–5× more than preventive maintenance over an asset’s life cycle.

3. The Financial Impact of Preventive Maintenance

Preventive maintenance requires planning, but it’s a budget-friendly long-term strategy.

Benefits:

- Lower repair and replacement costs

- Predictable maintenance scheduling

- Reduced downtime (planned vs unexpected)

- Better safety compliance

- Extended asset lifespan

According to industry benchmarks:

A well-implemented preventive maintenance plan can reduce total maintenance costs by 20–30% and equipment downtime by 40–50%.

4. Cost Comparison: Preventive vs Reactive

| Cost Category | Preventive | Reactive |

|---|---|---|

| Planned Maintenance | Moderate | None |

| Emergency Repairs | Low | High |

| Downtime | Minimal | Significant |

| Replacement Frequency | Lower | Higher |

| Safety/Compliance Risk | Low | High |

| Total Long-Term Cost | Lower | Higher |

Preventive maintenance spreads smaller, predictable costs across time, while reactive maintenance creates unpredictable spikes.

5. Balancing Both Approaches

Not every asset requires preventive maintenance.

The right strategy depends on criticality and cost.

| Asset Type | Recommended Approach |

|---|---|

| Laptops, tablets | Preventive (scheduled checks and updates) |

| Furniture | Reactive (replace when worn) |

| HVAC systems | Preventive (scheduled servicing) |

| Power tools | Preventive (safety inspections) |

| Small accessories (mice, cables) | Reactive |

A hybrid model — preventive for high-value assets, reactive for low-cost items — is often the most efficient.

6. Predictive Maintenance: The Next Step

For organizations ready to move beyond time-based schedules, predictive maintenance leverages data and sensors to forecast failures.

Key technologies include:

- IoT sensors for performance tracking

- AI-based anomaly detection

- Automated maintenance scheduling

Predictive systems minimize both over-servicing and unplanned failures, delivering the best ROI for large asset fleets.

For how teams move from periodic scans to sensor-driven insights, see: The Next Generation of Asset Tracking: From QR Codes to IoT Sensors.

7. Implementation Checklist for Preventive Programs

- Inventory all assets — know what you maintain.

- Categorize by criticality — prioritize key assets.

- Set inspection intervals — monthly, quarterly, or usage-based.

- Automate reminders — using digital asset management tools.

- Record all maintenance actions — build a full history.

- Analyze cost trends — compare planned vs emergency repairs.

This creates a feedback loop for continuous improvement.

To keep that history audit-ready (timestamps, evidence, and a consistent cadence), use: Inventory Audit Checklist: What to Verify and How Often.

8. Measuring ROI on Maintenance Strategies

To evaluate effectiveness:

- Track mean time between failures (MTBF)

- Compare planned vs unplanned downtime

- Calculate cost per asset per year

- Monitor repair frequency trends

A drop in emergency costs and downtime is the clearest sign your preventive maintenance program is working.

Conclusion

Preventive maintenance isn’t just about fixing things early — it’s about avoiding disruption altogether.

While reactive maintenance may seem cheaper in the short run, preventive strategies consistently lead to lower long-term costs, higher productivity, and greater reliability.

A proactive approach turns maintenance from a cost center into a strategic advantage.

Related reading

Try InvyMate

Start tracking assets with QR codes and scheduled audits.