How to Transition from Paper Logs to Digital Inventory Systems

Learn how to move from paper-based inventory logs to digital systems. Step-by-step guide for small businesses to save time and reduce errors.

Introduction

Many small businesses still rely on paper logs or notebooks to track inventory. While it feels simple and low-cost, paper quickly becomes a bottleneck — messy handwriting, missing pages, and endless manual counts.

Transitioning to a digital inventory system isn’t just about modernization. It’s about improving accuracy, saving time, and building a scalable foundation for growth.

This guide walks you through the step-by-step process of moving from paper to digital inventory systems, highlighting best practices and common pitfalls to avoid.

What Are Digital Inventory Systems?

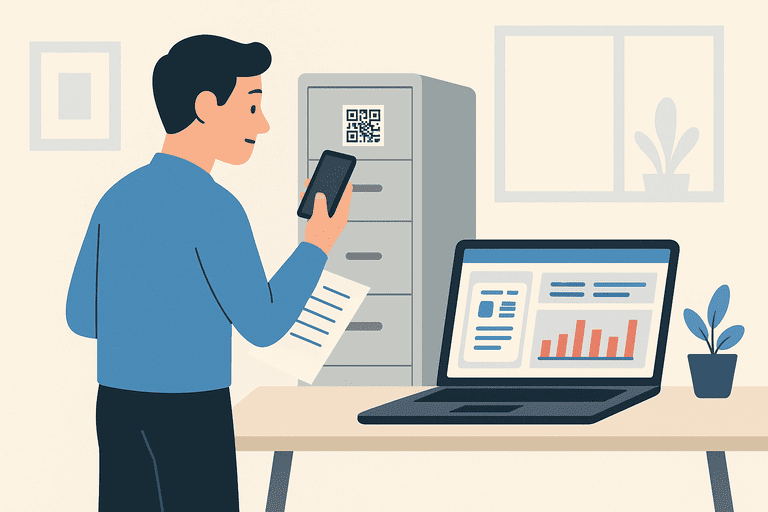

A digital inventory system is software that helps businesses track their assets, stock, or equipment electronically. Instead of writing down entries on paper, you can:

- Scan items with a phone or barcode scanner

- Record who used an asset and when

- Get real-time updates on stock levels

- Generate reports automatically

Popular systems often include mobile apps, QR code tracking, and cloud-based dashboards — making them far more powerful than paper logs.

Problems With Paper Logs

If you’re still using paper, you’re likely facing these issues:

- Errors and inconsistencies — human handwriting mistakes, missing lines, duplicate entries.

- No accountability — hard to tell who logged what and when.

- Time-consuming audits — searching through pages instead of one-click reporting.

- Lost records — coffee stains, misplaced binders, or damaged paper.

- Scalability issues — paper is fine for 10 items, not 500.

Digital systems eliminate these bottlenecks.

Step-by-Step Transition Process

Step 1: Assess Your Current Paper Logs

- What data do you record now? (e.g., item name, date, quantity)

- Which details are missing? (e.g., asset location, responsible employee)

- How many assets or inventory items do you need to track?

This assessment helps you set up a digital system with the right fields.

Step 2: Choose the Right Digital System

There are three main options:

- Spreadsheet tools (Google Sheets, Excel): Free, but still manual.

- Inventory-specific software (like InvyMate): Includes check-in/out, QR code scanning, and reporting.

- ERP systems: For large enterprises with complex needs.

👉 For small to medium businesses, specialized inventory software is usually the sweet spot — powerful but easy to adopt.

If you’re tempted to “just use spreadsheets”, this explains the core gaps you’ll hit quickly (history, accountability, and workflows): Why Spreadsheets Don’t Work for Asset Tracking (And What to Use Instead).

Step 3: Clean and Organize Data

Before migrating:

- Standardize item names (avoid “Laptop Dell” vs “Dell Laptop”).

- Remove duplicates.

- Assign categories (IT, furniture, consumables).

- Decide if you’ll use barcodes or QR codes for tracking.

This ensures your digital database is accurate from day one.

If you want a quick guide on picking labels and scanning workflows, see: Barcode vs QR Code Tracking: What’s Better for Inventory?.

Step 4: Digitize the Records

- Enter items into the new system manually or via bulk CSV import.

- Assign each item a unique ID.

- Apply labels (QR codes or barcodes) to physical items for quick scanning.

Step 5: Train Your Team

- Show staff how to check assets in and out digitally.

- Establish rules: “No item leaves without a scan.”

- Use role-based access to limit who can add/edit records.

A successful transition depends on people, not just technology.

To keep edits safe as you add more users, define roles and approvals early: Role-Based Permissions in Inventory Systems: What’s Safe.

Step 6: Run Both Systems in Parallel

For 2–4 weeks, keep using paper logs and the digital system. This allows you to:

- Verify data accuracy.

- Catch missing items or errors.

- Build confidence before going fully digital.

Step 7: Fully Switch to Digital

- Stop maintaining paper logs.

- Store old records securely for reference.

- Commit to updating only the digital system.

From here, you’ll start seeing the real benefits — faster audits, accountability, and real-time insights.

Benefits of Digital Over Paper

1. Time Savings

Audits that took hours now take minutes with scans and reports.

2. Better Accuracy

No more handwriting errors or misplaced notebooks.

3. Accountability

Every item checked in/out is tied to a person.

4. Real-Time Insights

Know exactly what you own and where it is.

5. Scalability

Whether you have 50 or 5,000 items, digital systems grow with you.

Best Practices for a Smooth Transition

- Start simple: Track only the most important fields first. Add complexity later.

- Use QR codes: They’re faster and hold more data than barcodes.

- Schedule regular audits: Even digital systems need verification.

- Back up your data: Cloud-based systems usually do this automatically.

- Involve employees early: Resistance drops when staff see the benefits.

👉 Check out our article on QR Code Inventory Tracking for a practical way to enhance your digital setup.

Common Mistakes to Avoid

- Migrating messy, inconsistent data without cleaning it.

- Skipping team training.

- Relying only on spreadsheets — they feel digital but lack automation.

- Not setting policies (e.g., “Every tool must be scanned when borrowed”).

Conclusion

Transitioning from paper logs to digital inventory systems may feel daunting, but the payoff is worth it. You’ll save time, reduce errors, and gain real-time visibility into your assets.

Start with a clear plan: assess, choose software, clean data, train your team, and make the switch step by step. Within weeks, you’ll wonder how you ever managed with paper.

Related reading

Try InvyMate

Start tracking assets with QR codes and scheduled audits.