Managing Shared Tools in Workshops and Makerspaces

Learn how to manage shared tools in workshops and makerspaces with smart inventory systems to improve accountability and reduce losses.

Introduction

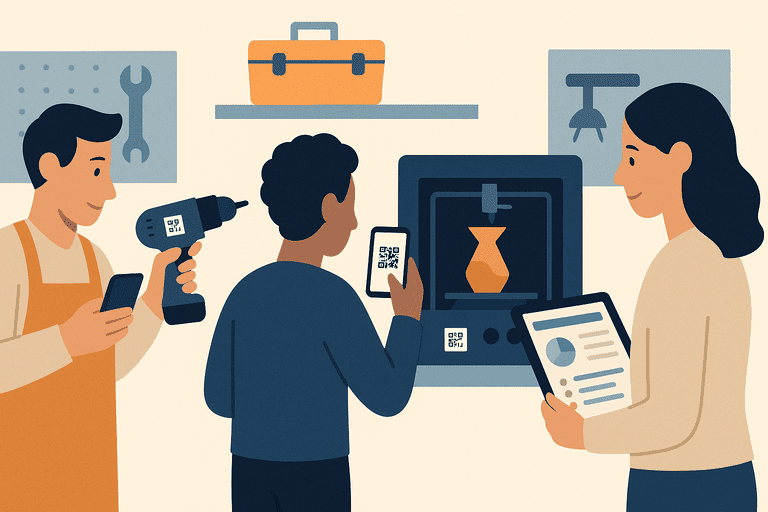

Workshops and makerspaces thrive on collaboration. Members share drills, 3D printers, saws, soldering irons, and other valuable tools. But with dozens of people using the same resources, one challenge always emerges: keeping track of who is using what and ensuring everything is returned in good condition.

Without a system in place, tools go missing, equipment breaks without accountability, and members waste time searching for the right items.

This article explores how to manage shared tools in workshops and makerspaces effectively, using best practices and modern tracking tools.

Why Shared Tool Management Is Essential

Makerspaces and workshops are built on trust, but trust alone doesn’t prevent issues such as:

- Lost tools — small items like screwdrivers or wrenches often vanish.

- Broken equipment — without logs, nobody takes responsibility.

- Downtime — members wait for tools because usage isn’t tracked.

- Budget strain — frequent replacements increase costs.

A proper tool management system keeps resources available, reduces costs, and ensures fairness among members.

What Should Be Tracked in Makerspaces?

Key categories include:

- Power tools (drills, saws, grinders).

- Hand tools (wrenches, screwdrivers, pliers).

- Specialized equipment (3D printers, CNC machines, laser cutters).

- Consumables (solder, filaments, sandpaper, adhesives).

👉 See how coworking-style environments benefit from tracking in our article on How Coworking Spaces Track Furniture, Electronics, and Supplies.

If accountability is the main issue, start with the underlying workflow problem (clear ownership + usage history): Why Shared Inventory Fails Without Accountability (and How to Fix It).

Tools for Managing Shared Equipment

1. QR Code & Barcode Tracking

- Label every tool, from small wrenches to large machines.

- Members scan codes when borrowing and returning.

- Works with inexpensive labels and smartphone apps.

2. Inventory Management Software

- Software like InvyMate tracks all shared tools in a central dashboard.

- Logs who borrowed each item and when it’s due back.

- Generates usage and maintenance reports.

3. Check-In/Out Stations

- A dedicated kiosk or tablet at the tool room.

- Members scan items before taking them out.

4. Access Control (Advanced)

- RFID or smart locks for high-value tools like 3D printers or CNC machines.

- Access restricted to trained or certified members.

Step-by-Step Guide to Managing Shared Tools

Step 1: Audit All Tools

- List all hand tools, power tools, and machines.

- Note purchase dates, conditions, and replacement costs.

Step 2: Label Each Tool

- Apply QR or barcode stickers to all items.

- Use metal or tamper-proof labels for tools exposed to heavy use.

Step 3: Set Up a Digital Register

- Import tool data into inventory software.

- Create categories for hand tools, power tools, machines, and consumables.

To keep categories consistent (and reports reliable), define a simple class structure and naming rules: How to Segment Asset Classes for Better Reporting.

Step 4: Implement Check-In/Out

- Require members to scan tools when borrowing.

- Track who has which tool and for how long.

To reduce friction and prevent missed scans, use a streamlined checkout flow (especially in high-traffic tool rooms): Designing an Asset Checkout Flow UX That Works.

Step 5: Train Members

- Show how to scan tools.

- Emphasize responsibility and proper return policies.

Step 6: Schedule Maintenance

- Log service intervals for machines (e.g., CNC maintenance every 6 months).

- Track broken tools to repair or replace promptly.

Benefits of Digital Tool Tracking

Reduced Losses

Every item is traceable, reducing the chances of missing equipment.

Fair Accountability

Members know they’re responsible for borrowed tools, improving care.

Lower Replacement Costs

Fewer lost or damaged tools = smaller budgets spent on replacements.

Increased Member Satisfaction

Tools are available when needed, reducing wait times and frustration.

Better Resource Planning

Reports show which tools are most in demand and which are underused.

Example: Community Makerspace

A community makerspace with 80 members struggled with:

- Missing hand tools every week.

- Broken 3D printers without repair logs.

- Complaints about unreturned equipment.

After switching to InvyMate’s QR-based tool tracking:

- Every item received a QR code label.

- Members scanned tools when borrowing.

- Admins viewed usage history and overdue items in real time.

- Lost tools dropped by 70% in six months.

Best Practices Checklist

- Label every tool with a QR or barcode.

- Keep a central digital asset register.

- Train members on check-in/out procedures.

- Track consumables separately to prevent shortages.

- Schedule and log equipment maintenance.

- Run quarterly audits for accuracy.

Common Mistakes to Avoid

- Only tracking large machines — small tools add up in cost.

- Skipping audits — data becomes unreliable over time.

- Using only paper logs — they’re slow and error-prone.

- No clear policies — without rules, members don’t feel responsible.

Conclusion

Managing shared tools in workshops and makerspaces is more than organization — it’s about ensuring fairness, reducing costs, and keeping members productive.

By labeling tools, adopting digital check-in/out systems, and running regular audits, you can transform chaos into efficiency.

Related reading

- How Coworking Spaces Can Track Furniture, Electronics, and Supplies

- Asset Tracking in Education: Lab Equipment, Tablets & Tools

- Facilities Management: Keeping Track of Shared Equipment and Rooms

- Asset Tracking in Educational Institutions (Schools & Universities)

- Healthcare Inventory Tracking: Why Accuracy Saves Money

Try InvyMate

Start tracking assets with QR codes and scheduled audits.